Do you want to be informed on new Posts on this Thread? (members only)

| S&S Swan Maintenance - Boat Electrical system a mess - New Panel needed |

|---|

|

Join Date: 15 April 2011

Posts: 393 |

||

|---|---|---|

|

Boat Electrical system a mess - New Panel needed |

|

Join Date: 27 January 2011

Posts: 140 |

||

|---|---|---|

|

Hi Chris, last year we added a galvanic isolator and a leakage circuit breaker to our shore power setup. At the moment I am working on standardizing the 220V sockets. We have a mix of French, German and UK sockets on the boat. A funny indication of previous ownership, but it requires a number of adapters at board. Christian IF 411/028 |

|

Join Date: 20 February 2007

Posts: 119 |

||

|---|---|---|

|

Hi Chris:

|

|

Join Date: 16 May 2009

Posts: 252 |

||

|---|---|---|

|

Hiro - |

|

Join Date: 15 April 2011

Posts: 393 |

||

|---|---|---|

|

Dear Christian (my full name too!), Thank you for your reply. Yes, i agree, it's time to add the galvanic isolator. I have done a little research since I posted and it seems that the Fail-Safe designation is the type to get. For around $200 USD I think I can include an isolator in my grounding line. It also seems that the isolator may help in the case of an AC short which may not be apparent but is allowing 110 volt current to be flowing into the surrounding water; a danger for swimmers. Although, I really can't imagine anyone swimming in the water near my boat! Chris |

|

Join Date: 15 April 2011

Posts: 393 |

||

|---|---|---|

|

Dear Hiro, Thank you. As soon as I finish this note, I will immediately look at the maintenance section of this site to see your wiring project; I know it will be informative. With regard to AC, it came with the boat. I owned a Tartan 41, similar to our boats but not as seakindly, in the '80's which had only DC. I didn't miss the AC at all. My last boat had AC and I really didn't use it much. Now, however, I spend a lot of time at the dock and therefore will use the battery charger; etc. But...I think I could almost convince myself to make the change back to DC only - I had not even thought of that. Nigel Calder's books were my bibles while living aboard - those copies are gone so I need to get new ones. I like your idea of over-sized wiring and certainly color coding. When my business partner asks why I don't have someone else do the work, asside from the cost which is a big factor, there are so few really good mechanics, electricians; etc., that I find it's just easier to educate myself and do the job. Re-wiring, however, was not in this year's plan! So, I am really struggling to figure out how to get everything done. I need to stop all the leaks at the deck or all other work is moot. Thanks again. Chris |

|

Join Date: 15 April 2011

Posts: 393 |

||

|---|---|---|

|

Hi Hiro, I am embarrassed to say that I could not find the electrical section you mentioned. Chris |

|

Join Date: 20 February 2007

Posts: 119 |

||

|---|---|---|

|

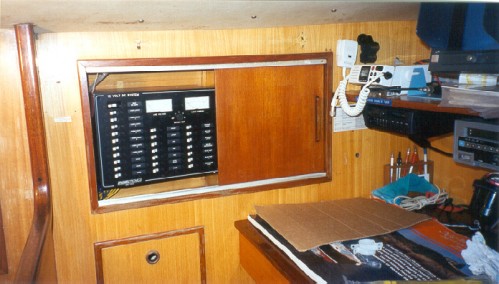

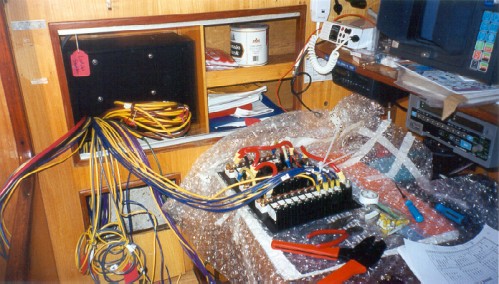

Sorry everyone I thought the new electrical panel image was posted already on the web site but it is not.

New Paneltronics electrical panel  New wiring in progress during new panel install New main wiring loom going forward (not in bilge) |

|

Join Date: 20 February 2007

Posts: 119 |

||

|---|---|---|

|

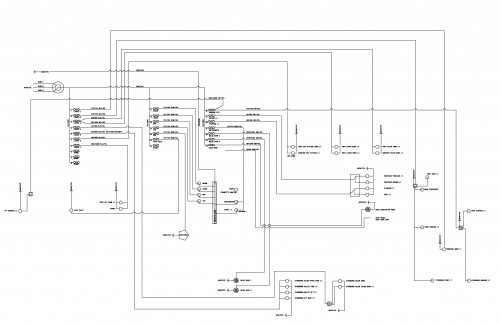

Here is the wiring schematic I used for my new wiring.

Wiring schematic for Hiro Maru |

|

Join Date: 20 February 2007

Posts: 119 |

||

|---|---|---|

|

Sorry everyone forgot this site does not like pdf files.

Hiro Maru amateur wiring schematic |

|

Join Date: 02 January 2008

Posts: 1547 |

||

|---|---|---|

|

Dear Geoff

|

|

Join Date: 15 April 2011

Posts: 393 |

||

|---|---|---|

|

Dear Professor, Thank you. My boat currently has GFCI outlets installed. I plan to replace all of the AC outlets. I am also aware of a GFCI breaker, are you referring to both? I am not really sure where such a breaker would be inserted – possibly it is the main breaker on the distribution panel. I just ordered the galvanic isolator - fail safe model which meets ABYC 2008 standards - and expect to receive it early next week. Then I will begin to wire the AC and then the battery charger. My original plan was so simple - replace the battery charger! Thank you for your concern and for mentioning the ground fault interrupter - I do not consider myself an electrician; I have my books and I read a lot, and I have a healthy fear of AC electricity. That's not enough; with your comments, help from members of this forum and the help of my friend here in the US who is an electrician, I can do the grunt work but have a professional check it all out! With warm regards, Chris |

|

Join Date: 27 January 2011

Posts: 140 |

||

|---|---|---|

|

Hi Chris, we installed a GFCI centrally, securing the complete the 220V distribution. There is plenty of information about this subject on the net. I was not aware that there are also GFCI outlets, as you seem to have on your boat. One article on the subject: GFCI. I am following all your projects on this forum, and I am equally impressed by the challenges you are confronted with, and your courage and determination to tackle them all over time. Christian IF 411/028 |

|

Join Date: 15 April 2011

Posts: 393 |

||

|---|---|---|

|

Dear Christian, Thank you for your note and kind words. I will read more about the central GFCI and have the Admiral (wife) find one as I continue to amass all the upgrades to my electical system. I expect that this project will not be started until later this summer. In the mean time, I continue with other projects; yesterday, I removed the fuel tank so that could inspect the sheaves for the trim tab. This was fortunate since the sheaves were totally seized. Since it's all clear in that area, i plan to clean and paint the area below the tank - almost fifty years of debris, oil, water and grease makes for a truly magnificent mess! I think ignorance may be my greatest driver! I have no idea what I am getting into until after it's too late! I will post picture in a different thread!. Thanks again. Chris |

|

Join Date: 02 March 2007

Posts: 83 |

||

|---|---|---|

|

Dear Chris,

|

|

Join Date: 15 April 2011

Posts: 393 |

||

|---|---|---|

|

Dear Hiro,

|

|

Join Date: 15 April 2011

Posts: 393 |

||

|---|---|---|

|

Dear Cosmo,

|

|

Join Date: 20 February 2007

Posts: 119 |

||

|---|---|---|

|

Sure Chris.

|

|

Join Date: 20 February 2007

Posts: 119 |

||

|---|---|---|

|

Hi chris:

|

|

Join Date: 30 January 2007

Posts: 461 |

||

|---|---|---|

|

Hi Hiro, |

|

Join Date: 15 April 2011

Posts: 393 |

||

|---|---|---|

|

Hi Hiro,

|

- Threads : 1702

- Posts : 10217

- Members: 821

- Online Members: 0