Do you want to be informed on new Posts on this Thread? (members only)

| S&S Swan Maintenance - Autopilot installation Swan 41 (Hydraulic drive) |

|---|

|

Join Date: 11 November 2023

Posts: 7 |

||

|---|---|---|

|

Autopilot installation Swan 41 (Hydraulic drive) Hello, we're new proud owners of s/y Pampero, Swan 41/048 1976. We'll be doing some repairs during the winter and one of the biggest is installing an autopilot. System consists of: -B&G Zeus 9"S 1. Does anyone have installation pictures of similar projects for hydraulic drive? 2. The Professor, wrote: "The recommendation is to install the autopilot ram fore and aft, this will reduce the maximum side loads on the rudder bearings" 3. Previous owner told, that rudder bearings are leaking, when motoring 6-7 kts. Are there any sealings/gaskets, or do we need to change the bearings? This obviously means removing the rudder axle? 4. Any tech tips and wise words are welcome =)

Best regards, Mari & Henri s/y Pampero |

|

Join Date: 29 January 2007

Posts: 1020 |

||

|---|---|---|

|

Dear Mari & Henri, If leaking won't stop it is likely you have to change the packing which is inside the gland (3/5 turns). matteo (47/069 Vanessa)  |

|

Join Date: 11 November 2023

Posts: 7 |

||

|---|---|---|

|

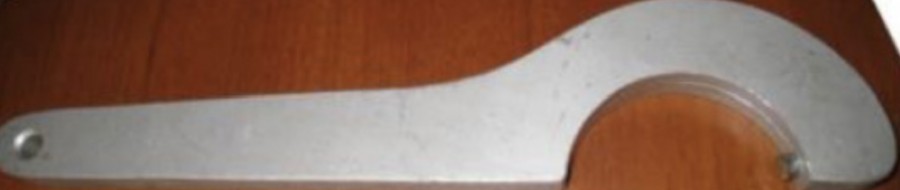

Thank you Matteo for very clear explanation. We'll inspect the rudder axle bottom carefully now that the boat is ashore. Previous owner had made an quick fix, probably without knowing how to tighten the bracket. Please find attached a picture. The tool is originally delivered with the boat? Yours, Henri

Rudder axle bottom |

|

Join Date: 20 July 2017

Posts: 115 |

||

|---|---|---|

|

Hi Henri, this looks like a very quick fix indeed; hopefully it will be an easy fix to do it properly following Matteo's advise! I believe the tool would/should have come with the boat originally ... hopefully the previous owners didn't get rid of it while 'decluttering' as it's an odd one and not immediately obvious what it is for. Almost happenend to us when we bought Kairos :-) Congratuations by the way for buying an S&S Swan, they will last forever when being looked after and give you many a days of joyfull sailing (some extra grey hairs, too, to be really honest ... but they tend to be worth it) Fair winds, Stefan SY Kairos (57/043) |

|

Join Date: 29 January 2007

Posts: 1020 |

||

|---|---|---|

|

Dear Mari & Henri, |

|

Join Date: 11 November 2023

Posts: 7 |

||

|---|---|---|

|

Thank you Matteo and Stefan, I'll follow these instructions and will post info + pictures.

Fair winds! Henri, s/y Pampero (41/048) |

|

Join Date: 29 January 2007

Posts: 1020 |

||

|---|---|---|

|

Dear Mari & Henri,  |

|

Join Date: 11 November 2023

Posts: 7 |

||

|---|---|---|

|

Many thanks Matteo! I'll try to find one from a local dealer here in Finland. Fair winds! Henri s/y Pampero (41/048) |

|

Join Date: 11 November 2023

Posts: 7 |

||

|---|---|---|

|

Hello, tomorrow I'll be visiting the boat and try to take some measurements for hydraulic arm. Does anyone have a picture of hydrdaulic arm installation as Professor suggested (longitudal)? It would be nice to see an example or an idea to help planning the structure. It seems that base for the arm needs to be laminated to hull. For materials I've been thinking are Coosa plate and fiberglass. Coosa plate with resin is strong enough to whitstand the forces. Another option could be divinycell. Fair winds, Henri

|

|

Join Date: 30 January 2007

Posts: 461 |

||

|---|---|---|

|

Hi Sypampero, I am replying only on the "position of the ram" problem because I remember discussing the topic with Lars. Ideally, the autopilot arm fixed on the rudder stock should be positioned exactly on the vertical of the rudder blade because, in such a way, at least theoretically, some of the momenta on the system are minimized. Practically, this is seldom possible and, moreover, there is no important reason to actually adopt this setup because the major cause of consumption of the rudder bearings are usually not due to the autopilot action. I suggest to take into consideration only the principal points when positioning the ram: 1) available space 2) solidity of the fixed point on the hull. Just for curiosity: in order to actually minimize the influence of the autopilot on the bearings, there should be two rams acting on two opposite arms; are you willing to do it? Naaaaa! Daniel, 411/004 Luna Menguante |

- Threads : 1703

- Posts : 10221

- Members: 821

- Online Members: 2