Do you want to be informed on new Posts on this Thread? (members only)

| S&S Swan Maintenance - Cracks in hull (Swan 48) |

|---|

|

Join Date: 15 December 2023

Posts: 5 |

||

|---|---|---|

|

Cracks in hull (Swan 48) Ahoy! My partner and I should be the new owners of Galatea, S&S Swant 48, hull number 13, in a few days. I attended the survey earlier this month. The surveyor commented that the hull, keel, and rudder were in much better shape than he expected! He found a couple of minor issues that don’t affect the seaworthiness of the boat, but may need some attention. We're so grateful for the S&S Swan Association and we're eager to hear the advice of ths forum. Here are his findings for the hull, keel, and rudder. “Keel and Ballast hairline crack was present along the forward sections of the ballast to hull joint. Hammer soundings made on the shallow keel root suggested that there was some looseness in the fairing at the forward end of the ballast to hull joint. Grind off the loose material and re-fair as desired. “The vessel had been built with an adjustable trim tab at the aft section of the keel. The tab had been eliminated and the aft section of the keel appeared to be a hollow fiberglass fabrication. Hammer soundings on the area were sharp and clear and moisture meter readings were only slightly elevated. No evidence of swelling or past weeping was present on the aft section of the keel. “Visually examined the ballast and keel for signs of past grounding and none were noted. The leading edge of the keel was free from damage. The exterior of the ballast was fair and smooth but there were some surface cracks in the fairing at several small areas of the lower mid-sections of the ballast. Re-fair as desired. “Rudder and Skeg “A stainless steel rudderstock and a stainless lower gudgeon attached to the full-length skeg supported the rudder. The rudder rotated freely and came up firmly against the stops, port and starboard. There was little play between the rudderstock and the rudderstock the tube in the hull. The small amount of the rudderstock that was visible was free from signs of pitting or corrosion. A semi-circular section of stainless was attached to the hull and aft edge of the skeg, immediately forward of the rudder. The stainless was free from signs of pitting or damage but the fiberglass fairing material was loose or had separated from the adjacent stainless. Grind off the loose material and re-fair as desired. “Sounded the rudder with a light plastic hammer for indications dull or hollow areas in the layup and the soundings remained sharp and clear. “Moisture meter readings made at random on the rudder ranged between 35 and 65 on Scale 1 on the Tramex meter on both sides of the rudder with the highest readings at the rudderstock entry and at the attachment at the lower gudgeon, which is common. No signs of swelling or weeping were present on the exterior of the rudder but a few stains were present on the port side at the connection with the lower gudgeon. Monitor the rudder for signs of weeping or swelling during annual haul outs and repair as found necessary in the future. “The full-length skeg appeared to be integral with hull. Hammer soundings made at random on the skeg remained sharp and clear. Moisture meter readings were generally low. Here’s what he said about his moisture meter. “Tramex meter readings are not percentages but simple scales that range between 1 and 100. Readings above 40 on Scale 1: ‘FRP in Saltwater’ or above 80 on Scale 2: ‘Low Moisture’ might indicate the presence of moisture in the outer laminates or adjacent core material if core material was used in the construction. “Moisture meter readings are only a guide, they are not a guarantee against present or future moisture intrusion into the laminates or any adjacent core material or against the existence of, or future development of osmotic blisters. A careful visual examination the bottom showed no evidence of osmotic blisters or moisture damage at the time of the survey.” So, do you think we should repair the issues with the loose or cracked fairing on the keel and the skeg by the rudder? The surveyor said it was optional, but to keep an eye on out. I’m inclined to have the repairs done for peace of mind. Also, what do you think of the rust stains on the rudder? Is that something I need to worry about or have investigated further? I attached some photos to show the issues. The photos look worse than in person. We’re so excited that the boat is free from major issues and we can’t wait to complete the purchase later this month! We have two more trips planned on Isbjørn, Galatea's sister ship, this spring, so I’m sure we’ll get many ideas on how to outfit our new boat for sailing. (Sorry for such a long post!) Sincerely, Robert and Bethany (Galatea Swan 48/13)  crack in faring at keel-to-hull joint (starboard)  crack in faring at keel-to-hull joint (port)  crack between stainless steel and skeg (port) |

|

Join Date: 29 January 2007

Posts: 1019 |

||

|---|---|---|

|

Dear Robert and Bethany, |

|

Join Date: 15 December 2023

Posts: 5 |

||

|---|---|---|

|

Hi Matteo,

Thank you for your reply! I have been reading the forum for a few weeks now, and I learned quickly that Lars Strom was an invaluable and dear friend to the S&S Swan Association.

We're relieved that we don't have to worry about the Swan smile! I also noticed some rectangular cracks in the faring on the keel. (Please see attached photo.) I assume these also are of no concern and are caused by differential thermal expansion of the metals in the keel? I noticed in one post that these are rectangular openings called galleries for the keel bolts.

As for the stainless steel faring pieces on the trailing edge of the skeg, since they are still well attached to the skeg, I don't have to worry about the loose faring material that sits atop the stainless steel, right?

Matteo, when you say that, “it is likely you have to overhaul the bearings,” will we go through the procedure, “Removal of Blade and Stock together”? In essence, will we go through the procedure followed by Isbjørn, which is described here, https://www.59-north.com/blog/2016/3/26/isbjorn-rudder-repair?

Sincerely, Robert and Bethany (Swan 48/13, Galatea)  Swan 48 keel showing rectangular cracks |

|

Join Date: 29 January 2007

Posts: 1019 |

||

|---|---|---|

|

Dear Robert and Bethany,   |

|

Join Date: 15 December 2023

Posts: 5 |

||

|---|---|---|

|

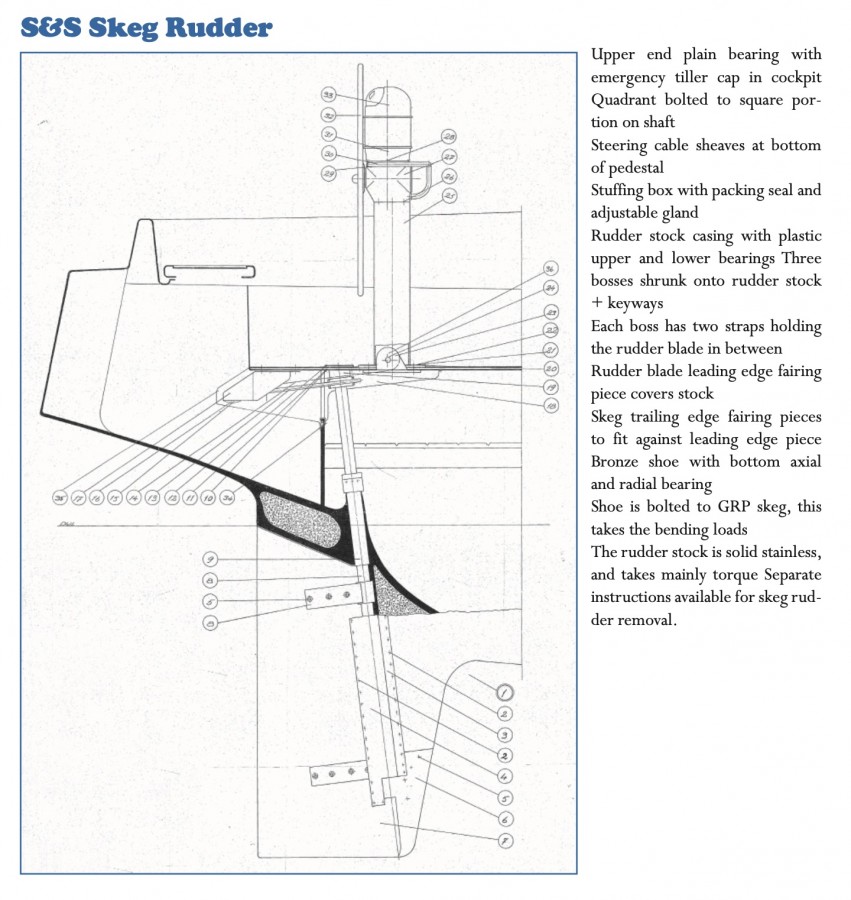

Hi Matteo, Thank you again for your excellent advice! We'll definitely check out the skeg fairing pieces as you suggested. Regarding the bearings, I understand that delrin is a suitable material for me to use to machine new bearings? To prepare, I'd like to get a better understanding of the exact location and shape of the bearings. I found this drawing (please see attachment), but I could not find a listing of each of the numbered items. Is such a listing avaiable? Thank you again for all your help and happy holidays! Sincerely, Robert and Bethany (48/13 Galatea) P.S. We are now official owners as we have the completed bill of sale!  excellent drawing of rudder |

|

Join Date: 29 January 2007

Posts: 1019 |

||

|---|---|---|

|

Dear Robert and Bethany,  |

|

Join Date: 05 August 2010

Posts: 162 |

||

|---|---|---|

|

Dear Robert and Bethany, congratulations on your new Swan 48 ... it may well be the last. There is not much that can come after a 48. The "S & S smile" cracks at the keel joint, as Matteo pointed out, are common and harmless. A couple of years ago we hit a rock, and the insurance insisted on hauling the boat and removing the top layers to take a look at the joint. I'll attach the pictures; you'll see a small longitudinal crack on one side of the keel but not the other (that's because we scraped it out on one side ...). You can also see that the filler material at the top forward part of the hull/keel joint is fairly thick. Lars told me the shape was designed according to hydrodynamic profiles. The last two pictures show the rudder skeg with the rudder removed (it is next to the skeg) plus the stainless steel pieces that cover the trailing edge of the skeg and leading edge of the rudder. Just to give you an idea of how this construction looks ... it is not a supporting element, just one more step towards the perfection these boats aimed at. Enjoy your 48 -- it is a great boat!  Covering material removed  Keel joint intact  Keel joint scraped out, filler visible |

|

Join Date: 05 August 2010

Posts: 162 |

||

|---|---|---|

One layer of new coat  Fairing pieces of skeg and rudder |

|

Join Date: 15 December 2023

Posts: 5 |

||

|---|---|---|

|

Hi Matteo and Martin, Thank you again for helping me learn about proper care of an S&S Swan! I think I can make new bushings for the rudder bearing on a lathe. The fun part will be removing the rudder blade and stock. I'm sure I can get help from the boat yard in supporting the rudder stock during removal and reinstallation. Martin, I noticed you painted everything prior to reassembly. Was that primer to help other materials adhere better? What sort of coating is it exactly? When the stainless steel faring pieces at the aft of the skeg are reinstalled, should I then cover the fairing pieces with filler material? Thank you for your encouraging words about our new (to us) S&S Swan! Sincerely, Robert and Bethany (48/13 Galatea) |

|

Join Date: 05 August 2010

Posts: 162 |

||

|---|---|---|

|

Dear Robert, good point -- I'd actually have to ask Peter Wrede about the material. To me it looks as if they simply sprayed on the same gelcoat and epoxi layers as they did with the rest of the underwater hull; there are actually at least three layers in different colors. We did not use any filler. And there is an intact surface beneath the fairing pieces, so I would not worry at all. By the way, when (and where) do you visit Isbjorn? We will sail Vellamo to northern Norway once more this year, so you might have the chance of meeting two 48s. Best wishes, Martin (Vellamo, 48/039) 2 48 @ 67 N |

- Threads : 1702

- Posts : 10217

- Members: 821

- Online Members: 1