Do you want to be informed on new Posts on this Thread? (members only)

| Sail & Rigging - Cleats vs fairleads |

|---|

|

Join Date: 30 January 2007

Posts: 461 |

||

|---|---|---|

|

Cleats vs fairleads |

|

Join Date: 16 May 2009

Posts: 252 |

||

|---|---|---|

|

Daniel: |

|

Join Date: 30 January 2007

Posts: 461 |

||

|---|---|---|

|

Geoff, |

|

Join Date: 30 January 2007

Posts: 461 |

||

|---|---|---|

|

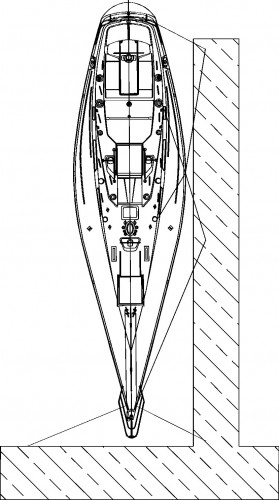

I enclose a picture of the CAD drawing I just finished.  |

|

Join Date: 16 May 2009

Posts: 252 |

||

|---|---|---|

|

Daniel |

|

Join Date: 30 January 2007

Posts: 461 |

||

|---|---|---|

|

Geoff, |

|

Join Date: 02 January 2008

Posts: 1547 |

||

|---|---|---|

|

Dear Daniel |

|

Join Date: 30 January 2007

Posts: 461 |

||

|---|---|---|

|

Dear Lars, |

|

Join Date: 02 January 2008

Posts: 1547 |

||

|---|---|---|

|

Daniel

|

- Threads : 1702

- Posts : 10217

- Members: 820

- Online Members: 2