Do you want to be informed on new Posts on this Thread? (members only)

| S&S Swan General - Max-Prop with Beta 50hp, Swan 431 |

|---|

|

Join Date: 06 January 2012

Posts: 67 |

||

|---|---|---|

|

Max-Prop with Beta 50hp, Swan 431 Hi, sorry, but have to start a new thread for Max-Prop pitch settings :) I've just replaced our old and trustworthy 4.108 with a new Beta 50hp. So it's time to adjust the pitch of my 3 bladed Max-Prop and need some help to do it correctly.

Facts about the old setup: Yacht: Swan 431-12 "CAID" Perkins 4.108: - max rpm from the engine when loaded: 3000 rpm giving around 40hp then. - boat speed approx. 8 knots with max rpm - cruising speed approx. 6,5 to7 knots with 2300-2500 rpm Borg-Warner Velvet drive: - ratio 2.92:1 (if I remember right, something around 3:1) Max-Prop: - 3 blades LH - diameter 520mm - pitch setting 20 degrees

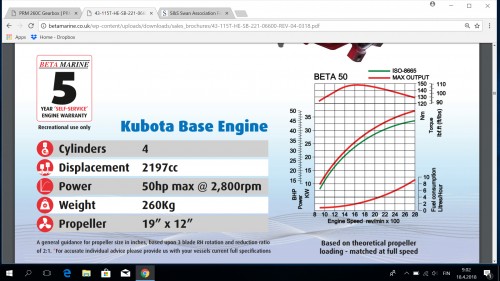

The new setup: Beta 50 hp - see the pic for technical data - lower max rpm 2800 and better torque compared to 4.108 PRM260C3 hydraulic gearbox (inline model): - http://www.prm-newage.com/p42-prm260c - ratio 2.94:1 Maxprop: - the same as before and will be used with left hand rotation. The PRM can handle bot LH and RH. Other: - some of the used cooling seawater will be directed along the original route with an extra 25mm hose to reduce the exhaust back pressure. - Beta original alternator is replaced with an Balmar 120A one reducet to 80-90A with a Balmar smart controller with suitable charge profile for the new energy storage. Batteries will be LiFePo4 with 360AH (2P4S) and controlled with Batrium BMS. But that's another story.

I'm looking for: - better fuel economy than with the old Perkins. It's been around 4-5 l/h but actually never really measured. - cruising speed with much lower rpm with less noise and vibrations

So, what is Your suggestion to Max-Prop pitch settings? I'm open to all suggestions, please share Your experiences! Soon will we be sailing again, IHe

|

|

Join Date: 02 January 2008

Posts: 1547 |

||

|---|---|---|

|

Dear IHe I would like to offer the following analysis of your engine installation particulars.

Your previous Max-Prop setting with the 4.108 absorbed 32 hp at 3000 rpm, this provided a good power reserve in case of a strong headwind, but also required slightly raised cruising rpms.

If you now set the pitch to 26 degrees, the engine will not quite reach the nominal 2800 rpm, but you will enjoy the same cruising speeds as before with 400 rpm less.

This meets one of your goals, low cruising rpms, but not the other, as the propeller now will absorb 0.4 hp more due to reduced efficiency. This is not a significant change, but for finding out more about the fuel consumption at cruising loads a Fuel Map-chart would be required from the engine supplier.

The fuel consumption curve on the engine data sheet assumes a propeller exactly matched to the engine, but mostly with Max-Prop, and also in this case, there is not an exact match. The Max-Prop pitch is set in steps of 2 degrees (assuming the Classic model) and in this case one step corresponds to about 8 hp change in power.

If the engine supplier requires that 2800 rpm is achieved for warranty, you could either reduce the pitch to 24 degrees, or reduce the propeller diameter slightly.

If there is no such warranty requirement, the recommendation is to use 26 degrees, and avoid using full throttle particularly in a strong headwind. The rpm should always be kept at least 250 rpm below the maximum achievable in the actual condition.

Pls feel free to ask questions

Kind regards

Lars

|

|

Join Date: 06 January 2012

Posts: 67 |

||

|---|---|---|

|

Dear Professot, thanks again for sharing Your unlimited knowledge and time to this forum. Yes, the propeller is the classic one. I had a strong feeling that the fuel economy was better before and has slowly decreased during the Years. The obvious reason was soon found after I just scraped off some layers of antifouling from its blade surfaces. I was a bit surprised to find out how many ”temporary” layers I’ve added there. Now the blades are polished to bare metal with mirror finish and I’ll hope it performs better.

I will start with Your suggestion of 26 degrees and will report to this thread how does it perform. Here’s a picture of the installation. It fits nicely and all the service points are easily reachable. As it is a bit smaller I’ll be able to add some more noise insulation around it. I will cut the Beta wiring cable and solder its wires to the Nautor orginal ones (seen in the pics) and place it watertightly under the SB floorboard near the engine. Theres never been any water there during our ownership. It was a nice surprice to find absolutely no corrosion or blackened copper wires from the Nautor wire loom. It might have been renewed already. The new gearbox needed some modification to the rear transverse beam at the engine bed and also something visible modifications to the bulkhead. It will be covered and hided with a small box made of original Nautor teak I happen to have.

Also the exhaust water collector had to be installed lower than before at the bottom of the boat. I have one question conserning that water collector installation. Beta installation instructions suggest that the height difference between the upper part of the water collector and the engine exhaust exit is at least 30cm. In this installation it’ll be around 20 to 25 cm. Some of the cooling water is not fed to the exhaust system as in the Nautor original installation. I’m afraid no one could say it’ll function for sure, but what is Your best quess about it. Will it be sufficinent not to flood the engine with seawater? The height difference is about the same as it was in the original 4108 installation and we’ve never had any troubles with it. Thanks again!

Beta 50 - electrical installation is about to begin  Some modification done to the bulkhead and the small bench  Exhaust water collector at the bottom of the Yacht |

|

Join Date: 02 January 2008

Posts: 1547 |

||

|---|---|---|

|

Dear IHe Thank you for the photos

Provided the water collector is straight aft of the engine exhaust bend your installation is OK. If to one side a large heeling angle may cause water to run back into the engine.

Part of the cooling water was led through a by-pass for reducing the amount of water injected into the exhaust, this reduces back pressure in the system. If there is a connection on the exhaust bend for back pressure measurement you could check this, and compare with the pressure given in the installation handbook.

If the water collector has a drain valve you could check how much water there is in the collector after shutting down the engine. Must not be full.

Kind regards

Lars

|

- Threads : 1702

- Posts : 10217

- Members: 820

- Online Members: 1