Do you want to be informed on new Posts on this Thread? (members only)

| S&S Swan Maintenance - Barient grinder arrangement - manufacturer & maintenance |

|---|

|

Join Date: 20 July 2017

Posts: 115 |

||

|---|---|---|

|

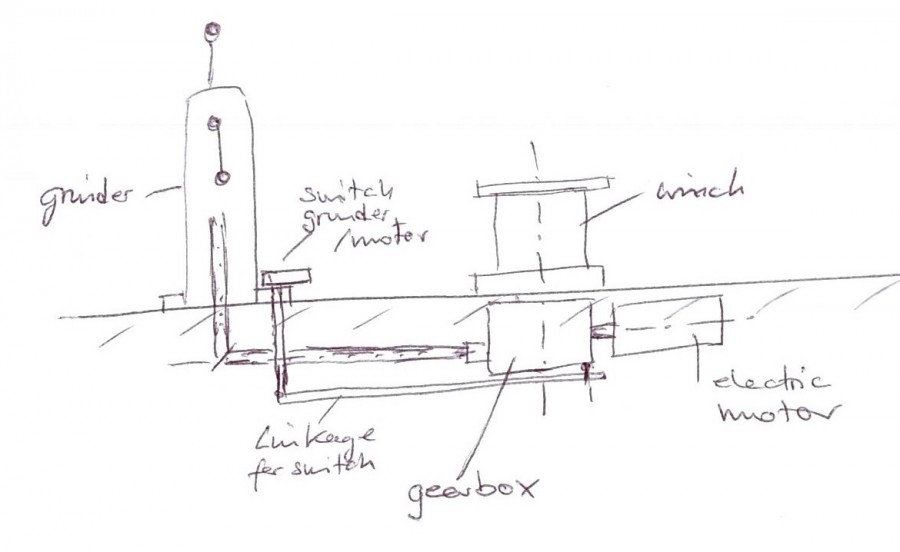

Barient grinder arrangement - manufacturer & maintenance Hi everyone, I was wondering if you could help. We have two Barient grinders on Kairos (Swan 57); each drives one of the main Genoa winches. Alternatively, the main Genoa winches can also be operated via electric motors. There is a mechanical selector lever at the bottom of the grinder pedestal to switch between the modes of operation. As you can hopefully see in the attached pictures, directly below the winch there is some kind of gearbox installed. The drive shaft from the grinder enters this gear box from aft, the electric motor is installed forward more or less directly on the gear box. The action of the selector switch is conveyed to the foreward side of gear box via a steel rod. The grinder system works a treat and we wouldn’t want to miss it; however, we noticed what we believe must be some significant wear and tear in the last season. Firstly, the gearbox appears to have some problems with the transmission of torque to the winch from both the grinder and the electric motor. This isn’t as smooth as it should be anymore, feels like it’s jumping a tooth. Might be an internal alignment issue or a damaged cog. Secondly and more worringly, the selector switches became very hard to operate and, at one occasion, did not prevent the grinder and the electric motor being connected at the same time. The selector was not properly operated to the fully switched position but this is obviously very dangerous as the electric motor then also turns the handles of the grinder. We did notice that both electic motors appeared to have ‘dropped’ a bit, thus interfering with the end of the selector lever rod; probably also not good for the alignment. Long story short, we will have to have the arrangement checked and serviced/repaired/made safe again. However, unfortunately we do not have any documentation on the system nor are there any clues with regards to the manufacturer. While our boatyard is quite happy to service all the ‘above-deck’ parts (and have done so in the past), they are somewhat reluctant to tackle the ‘below-deck’ mechanics without any idea what they let themselves (and us!) into. I have tried to search the vast internet but no luck so far – therefore, if anyone would have any information or hint that would be great – thank you! For example, is this a Barient or more likely an aftermarket arrangement? If the latter, would there be some ‘usual suspects’ that possibly could have fitted this? Probably in the Solent area or Ireland as Kairos was based here prior to us taking over in 2017 (ex ‘Serena B’, ex ‘Noonmark V’)… I have attached a sketch and a couple of photos that you might find helpful (apologies for the quality of the below-deck photos, not much room there to take them). Thank you very much for your help, and have a very Merry Christmas! Best, Stefan SY Kairos (57 - #43)  Sketch of system arrangement System above deck; selector lever at the bottom of the grinder pedestal  System below deck - drive shaft from grinder on the right, electric motor on left; rod from the selector lever in the foreground |

|

Join Date: 02 January 2008

Posts: 1547 |

||

|---|---|---|

|

Dear Stefan It is likely that your grinder/electrical system is installed later, such refinements were not available when the yacht was built. It is quite sure that all components came from Barient.

I happen to have an old 16-page Barient winch brochure, showing electric winches but no grinder systems. Assume you would appreciate a copy?

By Googling you can find the Barient patent for pedestal systems, and also some winch service manuals.

Where is your yacht located?

Merry Christmas!

Lars

|

|

Join Date: 02 January 2008

Posts: 1547 |

||

|---|---|---|

|

PS There is a website with complete Barient winch information except for the grinders.

http://www.cncphotoalbum.com/indexes/winches.htm

|

|

Join Date: 20 July 2017

Posts: 115 |

||

|---|---|---|

|

Dear Lars, thank you very much for your quick reply, very helpful indeed! Have downloaded the barient catalogue, the electric winsch system does look very similar to what we do have installed on Kairos - just the grinder connection and the 'selector switch mechanism' are missing. Will search for the grinder patent later - if you could send me the barient manual that would be great, thank you! Kairos is located in Glueckstadt, Germany at Yachtwerft Glueckstadt for the Winter. Merry Christmas to you, too, and thanks again for your help!

Best, Stefan |

|

Join Date: 02 January 2008

Posts: 1547 |

||

|---|---|---|

|

Dear Stefan Also the winch service manuals are found on the above mentioned website.

The gearboxes and selector switches are probably worn so much that they malfunction. It is unlikely that spare parts or drawings can be found.

Repair would require disassembly of these components, determination of the proper dimensions to make them work, and manufacture of new parts as required. This is a job for a very skilled mechanic having access to a metal shop.

The suggestion is have these components removed from the boat, and sent away for repair, but the mechanic should finally re-assemble the system in the boat and demonstrate that it is working properly.

Lars

|

|

Join Date: 20 July 2017

Posts: 115 |

||

|---|---|---|

|

Dear Lars, a very Happy New Year to you, and thank you very much for your help!

I will post updates on process and (hopefully) the solution here when available.

Best Stefan |

|

Join Date: 20 July 2017

Posts: 115 |

||

|---|---|---|

|

Hi all, a brief update on the above. First and foremost a big thank you to The Professor for his help and advise! Our boatyard has now managed to disassamble the port grinder system. Luckily this turned out to be pretty straight forward with no ceased bolts. It appears that no disassembly of any components above deck is required. The electric motor driving the shaft had dropped indeed, it was only held in place by the four bolts of the flange to the 'Tee Bevel Box' (gearbox) below the Genoa winch. This meant it was resting on the selector rod thus causing misalignement of the fork used to switch between the two inputs of the Bevel Box. As you can see i the picture the fork is badly worn as a result. The threads of the flange between the motor and the Bevel Box are still ok ish but will need re-cutting; the boatyard will also design a support bracket for the motor so that the force and momentum on the flange bolts will be reduced. Hopefully this will prevent any droping of the motor in the future. All of the bearings and gaskets of the components below deck are badly worn and will need to be replaced. The same holds tru for gearbox fork, and the whole system will then be realigned. Our boatyard is awaiting spare parts, fingers crossed that these are available. This should then hopefully bring the system back to good operating condition - in the meantime the boatyard will do the same on the starboard system. I assume all the above is due to years of little or no maintenance on this (and other, but more 'visible') system(s), a backlog which we inherited when we purchased Kairos. We are workig our way through but I guess it's also a matter of finding experts/people willing to tackle 'vintage' and unusal systems/solutions of which we have plenty on board. Needless to say that these systems tend to be very good and work well on our S&S Swans but they nevertheless are not every technician's cup of tea ... Best, Stefan Worn Bevel Box fork Flange and worn bearings of Tee Bevel Box |

|

Join Date: 20 July 2017

Posts: 115 |

||

|---|---|---|

|

Dear All, quick update on progress - all spare parts have arrived and the service of the main winches has been completed. One of the roller bearings of the 3rd gear came appart, these are discontinued now and were replaced by bronze sleeves. We have ordered four sleeves to replace the bearings on both winches. When dismantling the starboard system the boatyard found that the electric motor on that side was attached with a flange to a base plate mounted to the deck. The motor position was still good on the starboard side i.e. not dropped. This flange was not isnatlled (fro whatever reason) on the port system, hence the problem with the dropped electric motor. The base plate is still there so the boatyard will use it to support the motor. A few pictures below, will report back on performance once we are underway again, currently scheduled for late April. All the best Stefan SY Kairos (57 - 43/49) Destroyed roller bearing, third gear of winch Base plate and support flange of starboard motor Unused base plate on port |

|

Join Date: 20 July 2017

Posts: 115 |

||

|---|---|---|

|

Dear All, happy to report that our port grinder system has been assembled again and - according to our boatyard - is working as designed again. The starbord system was found to be in good order and was therefore only serviced. We have yet to check the system ourselves as the dreaded C currently prevents us to tend to Kairos in person, let alone go sailing. We hope we will be under way by June again, fingers crossed. I have attached a few more photographs below, thanks again to Lars for your help! Best Stefan Grinder T-piece Clutch in engaged position Clutch in disengaged position |

|

Join Date: 20 July 2017

Posts: 115 |

||

|---|---|---|

|

Dear All, we have now had the chance to sail Kairos for a couple of trips and are very pleased to report that the grinder system works a treat again. It's really good to see everything working as it should, especially now without the nagging feeling that the grinders might still be engaging after even when switched to the electric drive due to the worn clutch. This should be (is) now mechanically impossible (again); although we still might install an end-stop switch that (via a relais) cuts off the power to the electric drives when the clutch is in 'grinder' position at some point - just in case and for added peace of mind really. Really glad that we didn't follow the initial advice a few years back to get rid of the grinders altogether and rely on the electric units only. While we never considered this an option it once again shows that - while maybe not the easiest and cheapest route - most old but good systems can be retained/repaired with a little persistence, a good boatyard that is keen to get stuck in and - of course! - invaluable support from the forum! Thanks again for the latter. Hope everyone had a good season so far despite all the restrictions, fair winds Stefan SY Kairos (57 - 43/49)  |

- Threads : 1702

- Posts : 10217

- Members: 821

- Online Members: 0