Do you want to be informed on new Posts on this Thread? (members only)

| S&S Swan Maintenance - Mast + shoe corrosion |

|---|

|

Join Date: 27 August 2009

Posts: 44 |

||

|---|---|---|

|

Mast + shoe corrosion One more discovery while working on a renovation plan of my 41: the bottom of the mast appears corroded as well as the shoe. I have looked at previous threads on the corrosion of the bottom of the mast and it seems that best solution is to insert a stainless steal piece of metal inside the mast to reinforce it. Is my understanding correct? On the second point, should I replace the shoe? Does any one know if Nautor Swan spare parts still have extra shoes available? Ate there any other technical solutions to make sure the shoe is correctly restaured? Is there any particular piece of information I should relay to the technicians to help them carry out their work in the best possible manner? I have attached some pictures. Thanks in advance for any feedback. Christophe - Swan 41 #11    |

|

Join Date: 16 February 2007

Posts: 199 |

||

|---|---|---|

|

Bonjour Christophe, The problem of the corrosion of the mast foot is well known and well discussed in this forum. Look for a thread that was started on the 18th of Janaury. All information you need is there. What you should not do anyway is to insert stainleass steel in the foot of the mast. It will corrode even more. Insert aluminium. Cheers Philippe (47/050 Farouche) |

|

Join Date: 22 November 2008

Posts: 8 |

||

|---|---|---|

|

Hi Christophe,

|

|

Join Date: 25 July 2008

Posts: 30 |

||

|---|---|---|

|

Dear Christophe, You will find my experience just on the second page of thi forum. I just uploaded pictures of the actual situation. Ludovic (Rum trader 47') |

|

Join Date: 02 March 2007

Posts: 83 |

||

|---|---|---|

|

Dear Christophe, I took the mast out of my 41 last winter, and had similar mast corrosion. My mast had not been sleeved, and as the corrosion was not too bad I did nothing about it. However I had noticed that the shoe was always full of water ( usually rainwater) due to the drain holes being rather inadequate, so while the mast was out I drilled some 10mm holes right through the shoe and galvanised plate. I also added a thin plastic washer to the base of the shoe, and a plastic sleeve round the mast base to try and reduce galvanic corrosion.

regards Cosmo Little

|

|

Join Date: 23 February 2008

Posts: 15 |

||

|---|---|---|

|

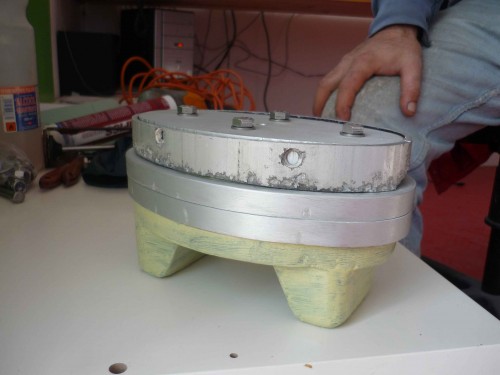

Bonjour, Christophe. Last summer we pulled our mast at the KKMI yard, www.kkmi.com in Richmond CA USA & found significant corrosion on the bottom of the mast. We ended up having the yard remove about an inch & then build a plug of high tech composite to restore the mast to it's original length. The plug also totally isolates the steel mast step/shoe from the base of the aluminum mast so we should never have the problem again. We did not have rust on the steel step/shoe. I'm sure if you contact Jock Maclean, our project manager, jock@kkmi.com you could get the specifications & details of how the repair was made. I have attached photos of the damage & new plug. There were drain holes put in the plug before the mast was restepped.    |

|

Join Date: 30 January 2007

Posts: 461 |

||

|---|---|---|

|

Hi Candy, |

|

Join Date: 23 February 2008

Posts: 15 |

||

|---|---|---|

|

Hi, Daniel. I have no idea exactly what the composite is that was used to construct the plug but it may be knows as "G-10". I do know it is very heavy for its size. That is why I referenced KKMI & Jock in my original post as they obtained the material & did the work. I'm sure he could provide design details as well as confirming G-10. We weren't there when they restepped the mast but with their attention to detail as a Swan yard, I'm sure it's tied into the bonding system. Candy, 44, #45

|

|

Join Date: 02 January 2008

Posts: 1547 |

||

|---|---|---|

|

Dear Candy and Daniel This is G-plate, glass reinforced epoxy laminate with a high fibre content, available in sheets. Stitched rovings and RTM or vacuum bagging required to get similar properties if you attempt to make your own version. On one Swan the corroded mast step was replaced with a structure built of G-plate, making it corrosion-free. Kind regards Lars |

|

Join Date: 22 November 2008

Posts: 8 |

||

|---|---|---|

|

you can see how I solve the corrosion mast problem on my 37..

|

- Threads : 1706

- Posts : 10229

- Members: 821

- Online Members: 2